It is critical when working in industrial environments to make sure that all work takes place safely. The permit to work ensures that all hazards are identified, risks are analysed and the necessary controls are implemented to protect against an incident.

In industrial plants, a great deal of effort is taken to ensure that every permit is adequately planned, prepared, issued and closed off.

Where isolations are needed, these are also tightly controlled to ensure there is no chance of any harm from the uncontrolled release of energy.

Enhancing the electronic permit to work system

An electronic permit to work system like IntelliPERMIT is ideal for controlling work in complex and potentially dangerous environments. But there is always space for improvement.

There are several opportunities for enhancing safety when IntelliPERMIT is linked to data from certain external systems, for example, supervisory control and data acquisition systems (SCADA), geographic information systems (GIS) and the industrial internet of things (IIoT).

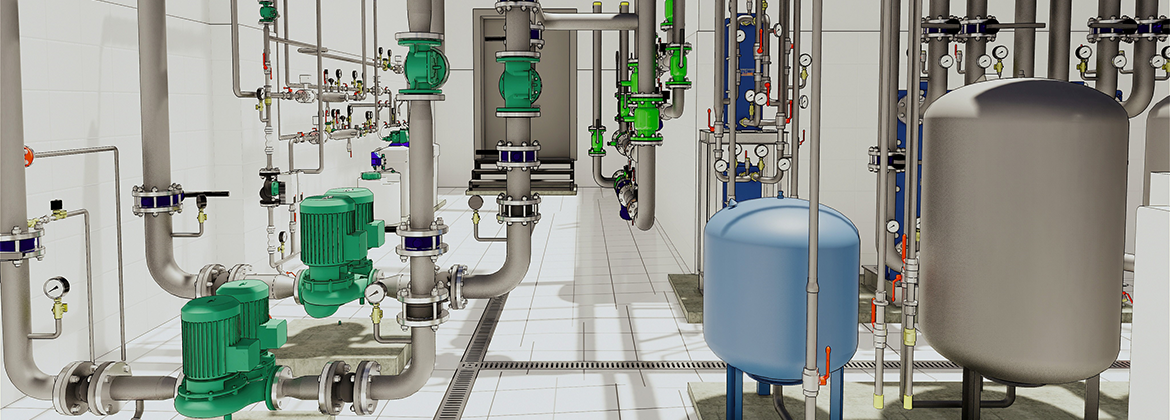

Some of these added safety benefits can also result from linking the permit into a 3D virtual model. This digital 3D representation, when connected to the live permit data, is known as a “digital twin”.

A digital twin is particularly helpful in compact or complex plants where it is essential to view work interactions during job planning.

As a production manager or maintenance planner, it is possible to gain additional safety insights that allow you to foresee problems better, plan more effectively, execute more efficiently and optimise the outcomes of work teams.

Building a 3D digital twin model for permit to work planning

Generating a detailed 3D model of a typical plant or factory is not as involved as it might initially seem. The process can be quick and cost-effective using modern software and making use of the services of a company that specialises in building industrial 3D models.

Images from a camera or drone can be combined with computer-aided design and drafting (CAD) drawings using advanced software techniques to build a 3D representation of the plant in the virtual world.

Experts in 3D modelling can also combine the data from images, engineering piping and instrumentation (P&ID) diagrams and isometric drawings to get a very accurate and realistic result.

Using a digital twin to enhance safety

Once a 3D digital twin model has been created, permit planners and issuers can use the virtual model in several ways to improve safety.

For example, just before venturing out onto the plant, workers can be shown the location of equipment and specific isolation points, as well as be made aware of any adjacent work planned in advance.

A 3D virtual model will be instrumental to safety in complex plants with multiple vertical processing levels, such as those on offshore oil platforms or in a typical oil refinery.

Quickly and accurately locating the right equipment in such environments can be a significant challenge for people unfamiliar with the plant.

But these benefits are not only limited to the smaller complex processing units. A suitable 3D model can also help workers get to the worksite more efficiently and safely when the work takes place over a large dispersed area, such as found in larger mines or power generation installations.

Other safety-related benefits can also result from the use of a digital twin. The overall system of planning work becomes more intuitive, more informative and more engaging to users.

Permit and maintenance planners can visualise potential conflicts between parallel work tasks in real-time and at different times in the future. They can avoid these conflicts by scheduling work accordingly.

This planning support can be very beneficial during shutdowns where congestion on the plant can increase significantly.

In an emergency, the accurate location of jobs taking place on the plant can allow response groups to quickly identify people at the highest risk and effectively evacuate and shut down safely.

Innovating with technology to enhance process safety

Adapt IT’s product group has been working for several years together with partners such as Sentient to unlock the potential of 3D digital twins.

The results have been very encouraging. The combined technology is proven to be very practical and demonstrably improves safety and efficiency in operations. You can see an example of this work in the following demonstration:

Source: Sentient Computing

For more information on how IntelliPERMIT and OpSUITE can help you better manage your process safety please contact the team at Adapt IT.

Source: Australian Mining